Products

China Wholesale Detach Gooseneck Trailer Exporters - 2 Line 2 Axle 40 Ton Low Bed Truck Trailer vehicle – Qingte Group

China Wholesale Detach Gooseneck Trailer Exporters - 2 Line 2 Axle 40 Ton Low Bed Truck Trailer vehicle – Qingte Group Detail:

Features

– Scientific design with high strength steel

– High loading capacity and longer service

– Professional customized Team

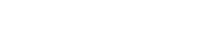

– build up the parameterized drawing model and verification of all components, avoiding assembly interference.

– Simulation and Analysis of Design is used in vehicle to promote product performance.

– High Strength full thickness Steel, H-shape design, which ensure Beam and frame’s toughness and strength.

– World famous brand spare parts like WABCO brake valve, JOST landing gear, YUEK,FUWA, BPW Axles ensure high quality and save maintenance costs

– Strong Loading Capacity 40-200 Tons Or Customized

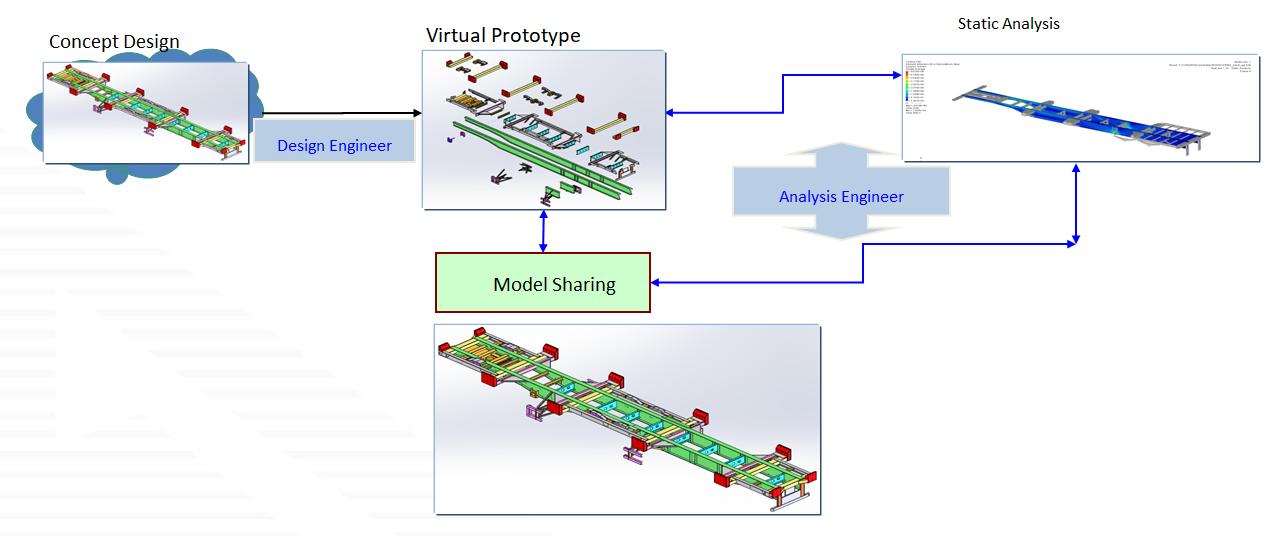

Low Bed Truck Trailer vehicle Specification

Process Guarantee

Welding Production Details Show

Material quality, Welding processing,Spare parts are the main element to ensure semitrailer stable quality and longer service capacity. Furthermore, the welding processing details is direct way to show factory operation technology. Qingte Low bed trailers adopt advanced submerged arc welding technology on the main beam welding to ensure the welding channel smooth and strong. Say no to the welding-opening problem. All the welders in workshop own the Welder’s qualification test certificate, a group of high quality staff can guarantee perfect welding details. In additional, all the welding slag will be polished to confirm smooth surface.

Low Bed Trailer parameters

|

2 Axle low bed trailer capacity |

30-40 tons. |

|

Axles |

YUEK,BPW, FUWA or Certificated China brand |

|

Steering |

Self Steering or hydraulic steering axles |

|

Spare parts |

JOST or China brand parking leg and king pin |

|

Chassis |

Standard Quality Steel usage |

|

Suspension |

Air or Mechanical Suspension |

|

Brakes |

ABS and EBS brake system |

|

Rims |

Steel Rims |

|

Tires |

Good brand tires |

|

Parking legs |

JOST,Turkish |

|

King pin |

JOST or China Brand optional |

|

Loading Ramp |

800 or 1000mm width pneumatic or hydraulic system |

|

Chassis |

Submerge arc welding technology with “H” shape design |

|

Platform |

4mm thick checkered plate covered, Rubber or Hardwood can be optional on the platform side |

Painting

A high quality beautiful trailer body is inseparable from fine division of processing and clean working environment. Qingte ferry coating painting line is divided three processing. Sand blast processing–Painting processing(primer painting and finishing coat )–Drying. Two sand blast houses, Four painting houses, Two Drying House make up the whole painting production line. Two electric flat cars are used to ferry the semitrailers/dumpers into and out of each house. Flat car runs smoothly and can realize automatic track alignment with each track. The ground drive chain is installed in the flat car and house for automatic entry and exit of the semitrailers/dumpers to improve the transport efficiency and meet the requirements of mechanized production.

• Sand blast processing deal with surface and accessories of chassis

• Painting processing(2 times primer painting and 2-3 times main painting )

• The Pantone color card color is optional for customized choice

• Drying processing ensure the whole body dry at the same time

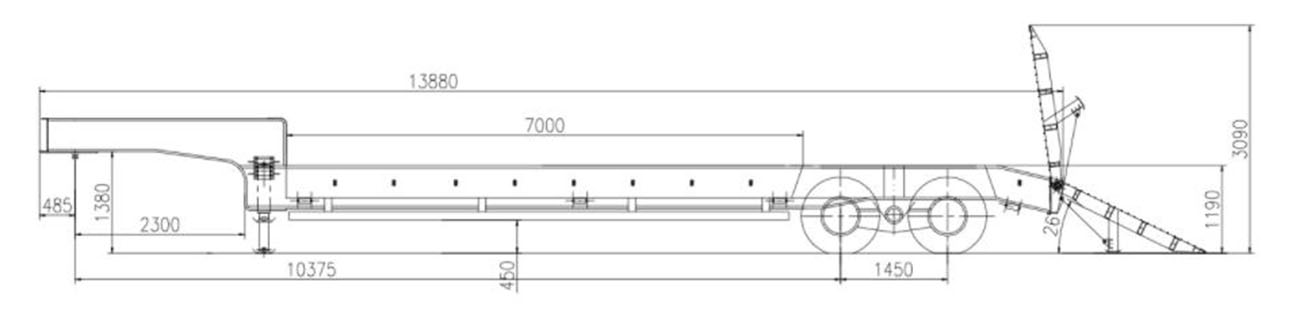

Application

–Heavy duty cargo Transportation like

Overweight pipe, prefabricated building, Chemical equipment

–Large transformer Transportation like

Heavy vehicle, rail vehicles, excavator

–Large model engineering equipment Transportation like

Mining machinery, forestry machinery, agricultural machinery

Shipping Ways

We are good at CKD/SKD situation package for OEM Semitrailer Factory and the whole semitrailer package for dealer or end user.

The CKD/SKD situation semitrailer can be shipped by container, and the whole semitrailer can be shipped by RORO ship or bulk cargo ship

Product detail pictures:

Related Product Guide:

we are able to provide good quality items, aggressive rate and best shopper assistance. Our destination is "You come here with difficulty and we provide you with a smile to take away" for China Wholesale Detach Gooseneck Trailer Exporters - 2 Line 2 Axle 40 Ton Low Bed Truck Trailer vehicle – Qingte Group , The product will supply to all over the world, such as: Danish, Wellington, Sydney, Our faith is to be honest first, so we just supply high quality products to our customers. Really hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products ! You will be Unique with our hair products !!

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.