Products

China Wholesale Street Sweeper Truck Exporters - 3 Axle 60 Ton Low Bed Trailer – Qingte Group

China Wholesale Street Sweeper Truck Exporters - 3 Axle 60 Ton Low Bed Trailer – Qingte Group Detail:

Features

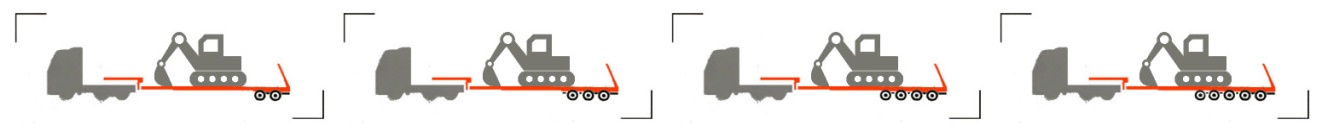

– Low bed trailers follow quality material and unique design

– High loading capacity and longer service

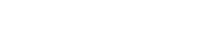

– Build up the parameterized drawing model and verification of all components, avoiding assembly interference.

– Simulation and Analysis of Design is used in vehicle to promote product performance.

– High Strength full thickness Steel, H-shape design, which ensure Beam and frame’s toughness and strength.

– World famous brand spare part, ensure high quality and save maintenance costs

– Strong Loading Capacity 40-200 Tons Or Customized

Low Bed Trailer Specification Process Guarantee

Welding Production Details Show

Material quality, Welding processing, Spare parts are the main element to ensure semitrailer stable quality and longer service capacity. Furthermore, the welding processing details is direct way to show factory operation technology. Qingte Low bed trailers adopt advanced submerged arc welding technology on the main beam welding to ensure the welding channel smooth and strong. Say no to the welding-opening problem. All the welders in workshop own the Welder’s qualification test certificate, a group of high quality staff can guarantee perfect welding details. In additional, all the welding slag will be polished to confirm smooth surface.

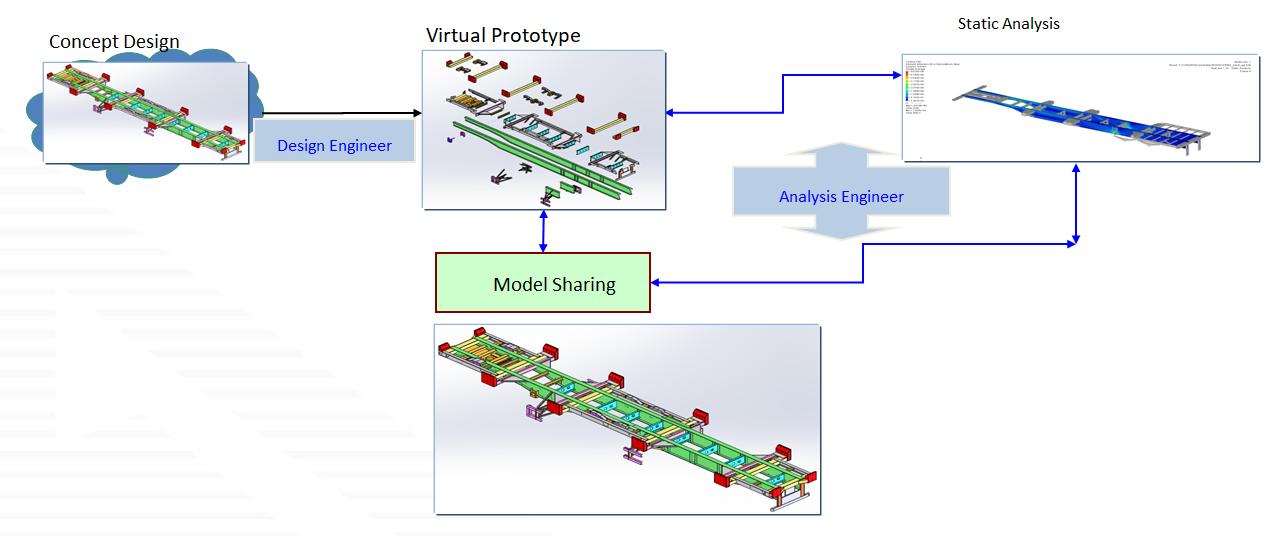

Low Bed Trailer parameters

|

Overall Dimension |

16750mmX2600mmX3100mm |

|

Main Beam Height |

550mm-580mm |

|

Upper Plate/lower Plate Thickness |

20mm |

|

Middle Plate Thickness |

10mm |

|

Loading capacity |

60Tons |

|

Platform Height |

1220mm |

|

Axles |

3 Axles |

|

Tires |

12 Units |

|

Lower platform |

5mm thickness checkered plate |

Application

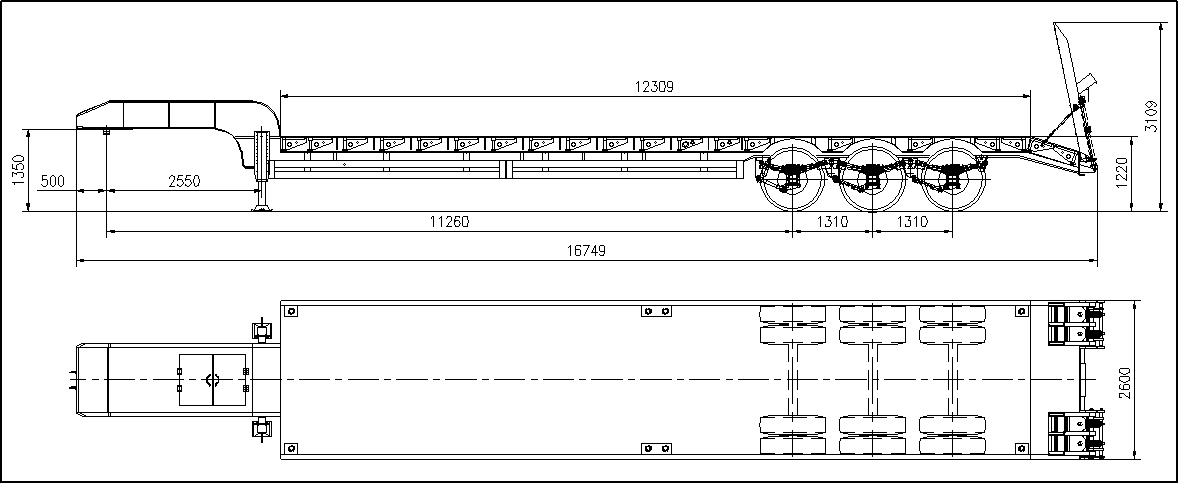

–Heavy duty cargo Transportation like

Overweight pipe, prefabricated building, Chemical equipment

–Large transformer Transportation like

Heavy vehicle, rail vehicles, excavator

–Large model engineering equipment Transportation like

Mining machinery, forestry machinery, agricultural machinery

Shipping Ways

We are good at CKD/SKD situation package for OEM Semitrailer Factory and the whole semitrailer package for dealer or end user.

The CKD/SKD situation semitrailer can be shipped by container, and the whole semitrailer can be shipped by RORO ship or bulk cargo ship

Product detail pictures:

Related Product Guide:

Dependable high-quality and fantastic credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality very first, client supreme" for China Wholesale Street Sweeper Truck Exporters - 3 Axle 60 Ton Low Bed Trailer – Qingte Group , The product will supply to all over the world, such as: Manchester, Argentina, Durban, "Create Values,Serving Customer!" is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, Please contact with us now!

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.