Products

China Wholesale Trailer With Tipper Manufacturers - QDT5250ZYSA Compression Garbage Truck – Qingte Group

China Wholesale Trailer With Tipper Manufacturers - QDT5250ZYSA Compression Garbage Truck – Qingte Group Detail:

Features

● Curved side gate structural box body ( high-strength plate ) and frame – type structural box body are optional ;

● All parts that are subject to friction for being in contact with garbage such as rear loader plate are of high – strength wear plate , which is able to withstand the repeated shock and friction due to compression of garbage ;

● All key components such as guide rails of compression mechanism are of machined parts ; the sliding blocks are of high-strength nylon ; al parts are precisely fit to ensure smooth operation ;

● Proximity switches, which are capable of non-contact sensor switching, are employed to control the action of compression mechanism; it is not only reliable and stable but also is obviously energy – saving ;

● The hydraulic system is of dual – pump dual – loop system , which makes bi – directional compression and high garbage compression density possible and is enjoying a prolonged service life of hydraulic system and significantly reduced energy consumption ;

● Imported multiple valves are employed to make bi-directional compression possible ; it is featured by reliable performance and high garbage compression density ;

● Operating system can be electrically and manually controlled ; it is convenient to operate with manual operation as an auxiliary option ;

● The compression mechanism is able to compress the garbage in both single – cycle and automatic continuous cycle modes and is able to reverse in case of jamming ;

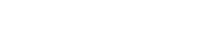

● The rear loader is configured with lifting, discharging and automatic cleaning functions and it can be more conveniently used ;

● Electrical – control automatic acceleration & constant speed device can not only meet requirements for loading efficiency but also can efficiently limit the oil consumption and reduce the noise level ;

● Hydraulic automatic locking mechanism is employed at the joint between front box body and rear loader; U sealing rubber strip that ensures reliable sealing is used to effectively avoid the leaking of sewage during loading and transportation of garbage ;

Major Technical Parameters

| Model | QDT5250ZYSA |

| Chassis model | BJ3257DLPJB- S |

| Engine type | SC8DK260Q3( optional as per requirement ) |

| Rated power ( kw ) | 192 |

| Laden mass rating ( kg ) | 10905,10605 |

| Kerb mass ( kg ) | 13900,14200 |

| Gross mass ( kg ) | 25000 |

| Maximum speed ( km / h ) | 81 |

| Tyre size | 11.00-20( optional as per requirement ) |

| Overall dimensions ( L x W x H )( mm ) | 8850,9150×2500×3100 |

| Wheelbase ( mm ) | 3575+1350 |

| Front overhang / rear overhang ( mm ) | 1465/2460 |

| Approach angle / departure angle (°) | 26/13 |

| Compartment effective volume (m3) | 15 |

| Loader volume (m3) | 2.2 |

| Hydraulic system pressure rating ( Mpa ) | 19 |

| Ground clearance of lower edge of filler port ( mm ) | Appr .1200 |

| Time for loader to complete one work cycle ( s ) | ≤25 |

| Time for push plate to complete discharging garbage ( s ) | ≤45 |

| Sump tank volume ( L ) | ≥400 |

| Manipulator turn – over mass ( kg ) | ≥600 |

| Garbage compression density ( kg /m3) | ≥800 |

Product detail pictures:

Related Product Guide:

Our group through specialist training. Skilled expert knowledge, sturdy sense of assistance, to fulfill the provider needs of shoppers for China Wholesale Trailer With Tipper Manufacturers - QDT5250ZYSA Compression Garbage Truck – Qingte Group , The product will supply to all over the world, such as: Netherlands, Moscow, Venezuela, With the growing of the company, now our products sold and served at more than 15 countries around the world,such as Europe,North America,Middle-east,South America,Southern Asia and so on. As we bear in our mind that innovation is essential to our growth, new product development is constantly.Besides, Our flexible and efficient operation strategies,High quality products and competitive prices are exactly what our customers are looking for. Also a considerable service brings us good credit reputation.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!