● All parts that are subject to friction for being in contact with garbage such as rear loader plate are of high-strength wear plate , which is able to withstand the repeated shock and friction due to compression of garbage ;

● All key components such as guide rails of compression mechanism are of machined parts ; the sliding blocks are of high - strength nylon ; all parts are precisely fit to ensure smooth operation ;

● Proximity switches, which are capable of non - contact sensor Switching, are employed to control the action of compression mechanism ; it is not only reliable and stable but also is obviously energy - saving ;

● The hydraulic system is of dual - pump dual - loop system and is enjoying a prolonged service life of hydraulic system and significantly reduced energy consumption ;

● Imported multiple valves are employed to make bi-directional compression possible; it is featured by reliable performance and high garbage compression density ;

● Operating system can be electrically and manually controlled ; it is convenient to operate with manual operation as an auxiliary option ;

● The compression mechanism is able to compress the garbage in both single-cycle and automatic continuous cycle modes and is able to reverse in case of jamming ;

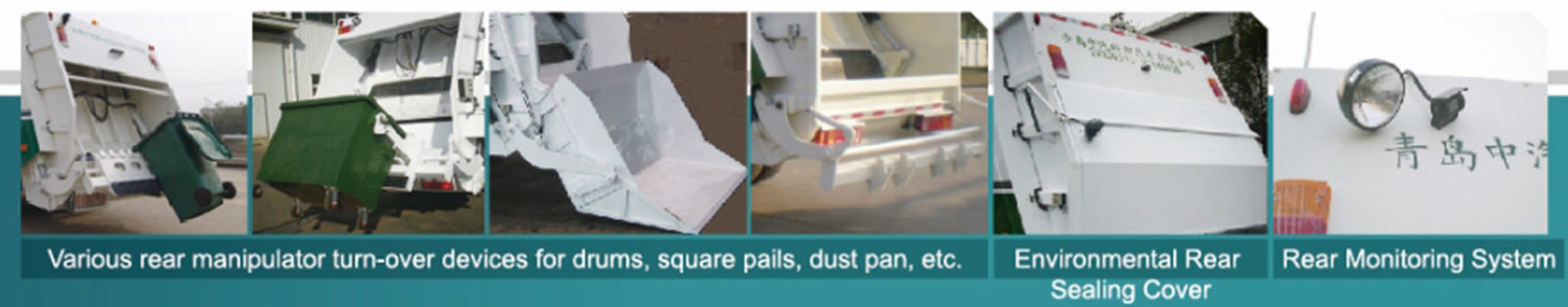

● The rear loader is configured with lifting, discharging and automatic cleaning functions and it can be more conveniently used ;

● Electrical - control automatic acceleration & constant speed device can not only meet requirements for loading efficiency but also can efficiently limit the oil consumption and reduce the noise level ;

● Hydraulic automatic locking mechanism is employed at the joint between front box body and rear loader; U sealing rubber strip that ensures reliable sealing is used to effectively avoid the leaking of sewage during loading and transportation of garbage ;